SOGEFI Air and Cooling

Innovation

SOGEFI’S

COOLING PLATE

IS PRODUCED WITH

The development of innovative and eco-responsible products represents a strategic opportunity to confirm and improve the market positioning of the company.

97%

Lower energy

consumption

99%

Lower greenhouse gas

emissions

E-Mobility Tech

Center Europe

The automotive industry, led by the main carmakers, is strategically oriented towards the production of vehicles with alternative mobility, reduced CO2 consumption and polluting emissions, as well as autonomous driving. Regarding material innovation, research activity is mainly focused on the use of lighter materials that allow for a reduction in weight and therefore in vehicle emissions, through revisiting product dimensions and through the replacement of steel.

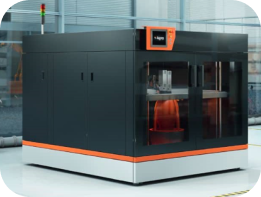

Furthermore, the activity is also focused on recycled materials and/or the possible recyclability of products at the end of their life. As a highlight of Sogefi’s commitment to the transition towards E-Mobility and a more sustainable approach, a new E-Mobility Tech Centre based in East of France has been developed a few minutes of German border. The facility is fully dedicated to E-Mobility developments and new products and is equipped with the biggest 3D printer in Europe.

Air & Cooling business unit, thanks to its specific technical and production skills, has great opportunities to respond to current and future needs of the market. On the E-Mobility side, the development of thermal management and cooling systems are key areas to support our customers’ transition to new engines. On the ICE side, development is mainly focused on the proposal of innovative mechatronic components that not only guarantee a significant downsizing of the main products offered, with a consequent reduction in fuel consumption, but also in an increase in combustion efficiency.

Among the main notable solutions are the development of the cooling plates and the cooling modules for thermal management applications. Thermal Management is the key to electrification of vehicles. Indeed, the management of calories is the key to increase the driving range of EV. Our products are aiming to reduce also material and energy consumption to manufacture a product. On product side, cooling plates is necessary to keep the battery pack at the right temperature. Cooling modules are necessary to distribute all coolant flows inside of the car.

New Sogefi Innovative Solution

Laser welded all-aluminum Cooling plate:

-

a superior mechanical resistance allowing weight reduction,

-

a flexible manufacturing process with low tooling costs.

-

TECHNOLOGICAL

ADVANTAGES -

SUPERIOR MECHANICAL STRENGTH OR WEIGHT REDUCTION

-

EXCELLENT SURFACE FLATNESS AND DIMENSIONAL STABILITY VS.STAMPED ASSEMBLY

-

NO CREVICE CORROSION / NOKOLOC ISSUES LINK TO BRAZING SOLUTION

-

FLEXIBLE MANUFACTURING PROCESS

WITH LOW

TOOLING COSTS -

COOLING

EFFICIENCY -

REDUCTION

OF ENERGY CONSUMPTION -

REDUCTION

OF CO2 PRINT

ECONOMICAL

ADVANTAGES

In the current context of

climate change and energy

prices rising

100%

95%

90%

85%

80%

-3%

Material Saving

-8%

Energy Saving

ACTUAL

SOLUTIONS